Contractor Saw

CNS™The SawStop® Contractor Saw offers versatility and safety.

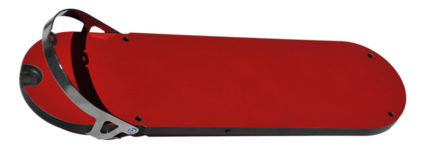

36-INCH T-GLIDE ADVANCE FENCE ASSEMBLY: The 36-inch T-Glide Advance Fence & Rail are made of heavy-gauge steel for sure lockdown and reliably square cutting for years without deflection. The multi-function aluminum fence face provides the ability to use in three positions, with a dovetailed groove for attaching accessories and jigs.

CONFIGURABILITY: Over 150 unique configurations, makes the Contractor Saw the most configurable SawStop saw. Adding a mobile base, sliding crosscut table or router table, are just a few of the ways to make this your ideal saw.

UNIVERSAL PERFORMANCE: The Contractor Saw offers versatility, reliability and safety for a variety of users. The cast iron table top (Cast Iron Wing Assembly, CNS-CIWA, sold separately) creates a better-than-hybrid performance in the shop at an affordable price.

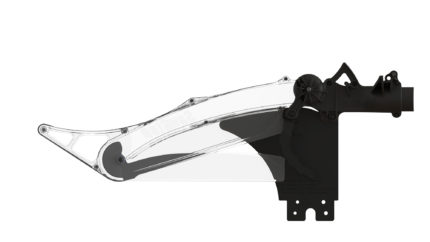

SAWSTOP PATENTED SAFETY SYSTEM: Stops a spinning blade on contact with skin. The blade stops in less than 5 milliseconds, and drops below the table, minimizing a potentially life-altering injury to a mere scratch.

RELIABILITY: The Control Box houses the on-off switch, power paddle, and on-board computer, and constantly checks that all systems are working to reliably keep you safe.

UNMATCHED QUALITY: The trunnion and arbor are built for precision, strength and stability. Poly v-ribbed belts reduce vibration and help ensure a great cut. Table flatness is measured diagonally at 0. 010” maximum gap.

Starting at: $2,476

Select Your Power:

Select Your Fence/Rail/Table:

Premium Fence

T-Glide Fence

T-Glide Advance Fence

Build & PriceSawStop’s commitment to quality, innovation, and safety over the past 20+ years has made us the best in the industry. Learn more about what makes a SawStop North America’s #1 Cabinet Saw

- 36" Professional T-Glide Advance Fence System provides smooth operation, three operating positions (high, low, L-fence), a dovetail groove for attaching accessories and jigs, precision measurement with two magnifying indicators (high and low position) and sure lockdown without deflection.

- SawStop Safety System stops on contact with skin.

- Includes Two Steel Extension Wings

- The most configurable saw in the SawStop lineup

- Dimension: 69 1/8" w, 45" d, 34 3/4" h

- Precision, performance and safety all come together to make this the right choice for experts looking for a reliable saw at an affordable price.

- (2) Steel Extension Wings

- (1) Miter Gauge

- (1) Micro Blade Guard

- (1) Riving Knife

- (2) Blade Wrenches

- (1) Push Stick

- (1) 10” Blade

- (1) Standard Lockdown Insert

- (1) Standard Brake Cartridge

- (1) Owner’s Manual

- (1) Assembly Instructions

- (2) Hardware Packs

- (1) 3mm Hex Key

- (1) 5mm Hex Key

- (1) 8mm hex Key

- (1) Blade Spacing Adjustment Gauge

36" Rip Capacity:CNS175-ATGP36: 36" T-Glide Advance Fence Assembly

Motor Option(s) (60Hz TEFC):1.75 HP available

Overall saw dimensions 36 in:69 1/8" W x 45" D x 34 3/4" H

Motor Configuration(s):CNS175: 1.75 HP, 120v, 14 A (user config. to 220v w/optional kit available for purchase).

Saw body footprint:25 3/4" W x 27" D (w/stand installed)

Cast iron table:20″ W x 27″ D

Cast iron table (w/ extension wings):44″ W x 27″ D

Extension wings:12″ W x 27″ D Stamped Steel (optional cast iron for purchase)

Extension table 36 in:23 3/4″ W x 27″ D

Shipping weights - w/ 36 in fence systems:350 lbs (4 boxes)

Shipping dimensions (saw body only):35" W x 30" D x 20" H

Shipping weight (approx.):240 lbs (table saw only)

Assembled weights - w/ 36 in fence systems:310 lbs

Weights - table saw only:225 lbs

Weights - (optional cast iron wings):35 lbs each

Blade:40-tooth, prof. grade, 5/8″ arbor

Blade diameter:10"

Blade tilt:Left

Blade kerf:0.118″ (3mm)

Blade plate thickness:0.078″ (2mm)

Max. depth of cut, blade at 0º:3 1/8″

Max. depth of cut, blade at 45º:2 1/4″

Max. rip, left of blade (w/36” or 52” T-Glide Fence):12"

Max. rip, right of blade (w/36” Fence):36"

Dado diameter:8" (requires dado brake cartridge & insert)

Dado max. width:29/32" (23mm)

Arbor diameter at blade:5/8"

Main bearing size:62mm OD x 30mm ID

Second bearing size:52mm OD x 25mm ID

Table in front of blade (max. elevation):10 5/8"

Table behind blade (max. elevation):7 1/8

Arbor Runout:0.001″ Maximum allowable runout

Table flatness measured diagonally:0.016″ Maximum gap

Blade alignment with miter slot:0.010″ Maximum displacement

Deviation of miter gauge indexing stops from actual:±0.25º

Alignment between splitter and blade:0.010″ Maximum difference

Miter slots T-shaped:3/4″ at top, 1″ at bottom, 3/8″ deep

Miter slots center:11 1/8″ center-to-center

Miter slots info:5 1/2″ (arbor flange to center of right slot)

Dust collection port diameter:4"

Riving knife / splitter thickness:0.090" (2.3 mm)

Blade guard:Standard polycarbonate, extends 1″ right of blade (opt dust guard for purchase)

Insert:zero clearance, phenolic core, melamine surfaces

Hand wheels:6″ diameter, cast alum. w/ ABS handle

Belts:V-ribbed belt – static dissipative

- Contractor Saw Quick Start Guide

- Espanol: Guía rápido de inicio de la sierra contrastista

- Contractor Saw Owner's Manual

- Contractor Saw Parts List

- Contractor Saw T-Glide Installation Instructions Poster

- Professional T-Glide Fence System (Part #: TGP) Owner's Manual (NOT RT Compatible)

- Professional T-Glide Fence System (Part #: TGP2) Owner's Manual (NOT RT Compatible)

- Professional T-Glide Fence System (Part #: TGP2.2) Owner's Manual

- Contractor Saw Mobile Cart (Part #: MC-CNS) Owner's Manual

- Professional T-Glide Advance Fence System (Part #: ATGP) Owner’s Manual

- Professional T-Glide Advance Fence System (Part #: ATGP-FA) Part's List

Safety

Proven technology that has saved thousands of woodworkers from catastrophic injury.

Quality

Dedication to best-in-class features and materials so you can deliver your best work.

Dealers

Our dealer network is made up of more than 600 authorized dealers who can help find the right SawStop for you.

Testimonials

Don’t just take our word for it. See what SawStop customers have to say.

Universal Performance

Contractor SawTM

Thousands of Fingers Saved

Explore the stories of individuals who suffered tragic incidents before buying a SawStop.

What Are People Saying?

Frequently Asked Questions

Any 10” standard-tooth steel blade with steel or carbide teeth can be used. Do not use blades with tooth “shoulders” (often called depth-limiting or anti-kickback shoulders), as these blades will take longer to stop in the event of an accident. Do not use blades with non-conductive hubs or teeth, as the safety system will not allow the saw to operate with these blades installed.

Any 8” standard-tooth steel stacked dado set (max width: 29/32”) with steel or carbide teeth can be used. A zero-clearance insert for your dado set must be purchased along with the required Dado Cartridge.

Do not use dado sets with solid-plate interior chippers, blades with molding heads, or “wobble” dado sets as the brake cartridge is not designed to stop those blade types. Also do not use blades with tooth “shoulders” (often called depth-limiting or anti-kickback shoulders), as these blades will take longer to stop in the event of an accident. Additionally, we recommend only using dado sets wherein the interior chippers have between two and four teeth per chipper to limit the impact on the saw during an activation.

SawStop manufacturers an 8” Premium Dado Set (BTS-DS8-2402) that can be used on all SawStop saws except the Compact Table Saw.

The SawStop safety system is designed for use with standard 10” blades with kerfs from 3/32” to 3/16”. Blades with kerfs much thinner than 3/32” should not be used because those blades might not be strong enough to withstand the force applied by the brake when it activates. As a result, those blades might deform and stop more slowly in the event of an accident, resulting in a more serious injury.

Blades with kerfs much thicker than 3/16” are heavier than standard 1/8” kerf blades. Therefore, those blades should not be used because they may stop more slowly than standard blades in the event of an accident, resulting in a more serious injury.

Similarly, stacks of 2 or more 10” blades should never be used on your SawStop saw as the combined weight of the blades may be too heavy to stop quickly. If you need to use a blade with a kerf thicker than 3/16”, use an 8” dado set with the optional SawStop 8” dado cartridge. The dado cartridge is designed for use with 8” dado sets up to 29/32” wide.

We do not have a scoring blade on any of our saws. Scoring blades cannot be used with our saws due to the stopping technology.

We do not recommend installing any kind of sanding disc or cutoff disc on a SawStop table saw.

The vast majority of commercially-available blades are accurate to their advertised diameter, and work well in SawStop saws. If your blade is larger or smaller than the advertised size, SawStop cast-iron saws allow for some adjustability of the blade/brake gap to accommodate. Jobsite Saw blade/brake gap is not adjustable, so users should not operate blades more than 1/16th inch diameter over the specified blade size. Never use a blade that does not “clear” the aluminum brake pawl.

Steel blades and dado sets with a lacquer finish or other coating on the teeth should not be used as the coating may inhibit or slow the speed at which the safety system detects skin contact. However, most coated blades do not cover the blade teeth. Those blades may be used on SawStop saws.

We sell only through authorized SawStop dealers. You can find a list of dealers on our site at https://www.sawstop.com/store-locator/. Please include your zip code in the “where are you?” field and be sure to select the correct model you are interested in viewing.

We also have a great build and price feature on our site that walks you through any saw configuration with accessory options, www.sawstop.com/build.

The SawStop safety system continuously performs many self-checks to ensure the components of the safety system are working properly. The safety system will not allow the motor to start (or to remain running) unless every component of the safety system is working properly.

In the vast majority of cases, coming in contact with the spinning blade will result in a minor cut. However, if your hand moves into the blade at very high speed, it is possible for you to receive a serious injury.

Generally, the safety system will not activate when a nail or staple is cut. Although conductive, these objects are not large enough to cause the safety system to activate unless they are grounded to the table or operator when they contact the blade.

The SawStop safety system will protect you even if you are wearing gloves. In that case, the system will trigger when the blade cuts through the glove and touches your skin. It is possible that the blade could snag on the glove and pull your hand into the blade, resulting in a slightly deeper cut. That is why SawStop recommends not wearing gloves when using a SawStop saw. However, if you decide to wear gloves, you are still protected.

If you activate the safety system’s brake, you will need to replace the brake cartridge and evaluate the condition of the blade for future use. Replacing the brake cartridge is simple and can take as little as 90 seconds to complete. A standard brake cartridge costs $95 USD and a dado brake cartridge $115 USD. SawStop saws are designed to absorb the force of activation and are not damaged by it.

When the safety system activates, it will sometimes damage one to more teeth on the blade. Some users discard and replace the blade, while others choose to have their blades inspected/repaired by a qualified specialist.

Yes, if you are using the red paddle to turn the blade on/off, the brake is still actively monitoring the coast down rotation. The yellow power switch is what powers the cartridge to begin monitoring the blade, so as long as that remains on, the cartridge will activate during coast down.

Bypass Mode deactivates the safety system’s braking feature, allowing you to cut aluminum, very wet/green wood and other known conductive materials. If you are unsure if material you need to cut is conductive, you can make test cuts using Bypass Mode to determine if it will activate the safety system’s brake.

SawStop saws cut most wet wood without a problem. However, if the wood is very green or wet (for example, wet enough to spray a mist when cutting), or if the wood is both wet and pressure treated, then the wood may be sufficiently conductive to activate the brake. If you are unsure if the material you need to cut is conductive, you can make test cuts using Bypass Mode to determine if it will activate the safety system’s brake. The red light on the control box will flash to indicate conductivity.

Cold ambient temperatures should not affect your saw mechanics. However, your saw’s brake cartridge contains “computer-like” parts that can be affected by extreme cold. If the cartridge is stored in temperatures well below freezing, the saw won’t turn on until the cartridge warms up. If you are in an extremely cold climate, we recommend removing the cartridge (which you can do with the blade in place) and storing it above freezing. Alternatively, some customers choose to leave the yellow “hard” power switch on all the time. This provides just enough heat to the cartridge to help ensure startup in spite of extreme ambient cold.

Our saws have a magnetic switch that prevents it from coming back on.

We recommend a minimum of 350 CFM (PCS/CNS) or 400 CFM (ICS) to the 4” port. Even the largest wet/dry vacuums or portable dust extractors will not supply the CFM needed for proper dust extraction from our cast iron table saws, so we recommend one of the many types of stationary solutions. To get a better understanding of comparing wet/dry vacuums to a stationary collector, visit http://woodworking.stackexchange.com/questions/768/what-advantages-does-a-dust-collector-have-over-a-shop-vac.

There are many different saws and other product choices on the market, each with its own installation and/or modification requirements. SawStop doesn’t test on the many other-brand aftermarket items, and therefore don’t have the necessary information to recommend your best result.

The manufacturer of the product you are interested in is likely the best place to start, as they may have a better idea of necessary modifications, if any are needed.

The Jobsite Saw features an enclosed dust shroud. Gates swing open to allow full access to the blade and cartridge, and magnet latches secure the doors in place for operation, delivering superior collection inspired by SawStop’s cabinet saws.

The Contractor Saw is a partially enclosed design. As such, while the dust collection is good, it will not collect as efficiently as the Jobsite Saw.