Steps to Replace and Adjust the SawStop Motor Belt (ICS and CB)

Service Procedure SP-ICS-190703-02

Tools & Supplies Required for This Procedure:

- 19mm combination wrench (a ¾” will work if no metric wrench available)

- SawStop blade wrench or short pry bar

- Motor Belt (SawStop part number CB104 192)

Procedure Steps:

(Before starting, please read instructions all the way through to ensure complete understanding)

Working through the belt access door:

- Remove the motor belt.

Working through the motor cover door:

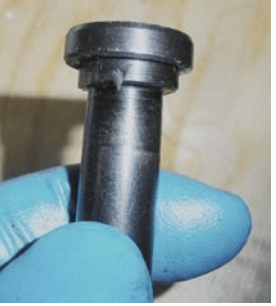

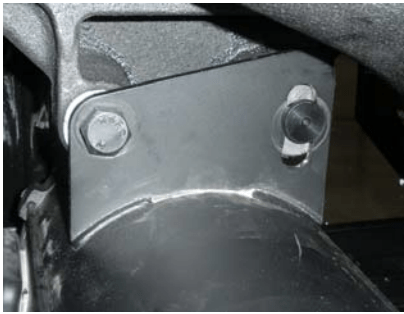

- (First time only) loosen and remove the motor bolt in the adjustment slot holding the motor to the bracket. Note that the adjustment bolt has a shoulder that fits into the curved slot to prevent it from turning while you loosen or tighten the nut to allow adjustment of belt tension.

- Reverse and reinsert the adjustment bolt. (I recommend reversing the adjustment bolt so that the nuts come out on the belt access side of the assembly; this will make the belt tension adjustment easier.) Tighten the nut snug and then loosen a quarter turn to allow movement to adjust the belt tension.

Working through the belt access door:

- Reinstall the motor belt on the pulleys, making sure the belt is lined up properly on the pulley grooves.

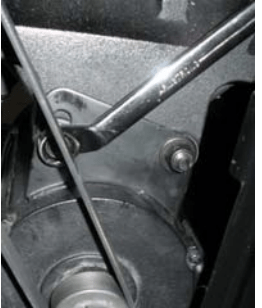

- Insert a pry bar (one of the blade wrenches works well for this) between the motor body and the bracket on the elevation mechanism, on the left side of the motor.

- Push down on the pry bar to increase belt tension. Tighten the nut on the adjustment slot.

The belt is properly tensioned if;

a) squeezing both sides between thumb and forefingers produces no more than ½” belt deflection, and

b) when plucked, the belt produces a note instead of a dead “thud”.

- When satisfied with belt tension, tighten both nuts and remove wrench/pry bar from the motor bracket. Turn the saw on and make a test cut to verify proper operation.

Note: after about 8 hours of operation, check and readjust belt tension to take up any slack. The new belt will likely have stretched a bit as it breaks in. It’s a good idea to check tension every so often to ensure maximum cutting efficiency and prolong belt life; a slipping belt will likely develop a glaze and need replacing.

Questions?

Contact the SawStop Customer Support Center with any questions or

suggestions:

Call: (503) 582-9934

Email: [email protected]