Quality Without Compromise

No one likes to compromise. Certainly, when SawStop set out to build the first SawStop Cabinet Saw, compromise was an unacceptable notion. Just as there could be no doubt that the saw’s legendary safety system would respond to contact in less than 5 milliseconds, there could be no doubt of the strength and durability of this new saw. Debuting a new saw to a crowded market of long-time favorite saw brands would be a challenge. SawStop had to bring our best.

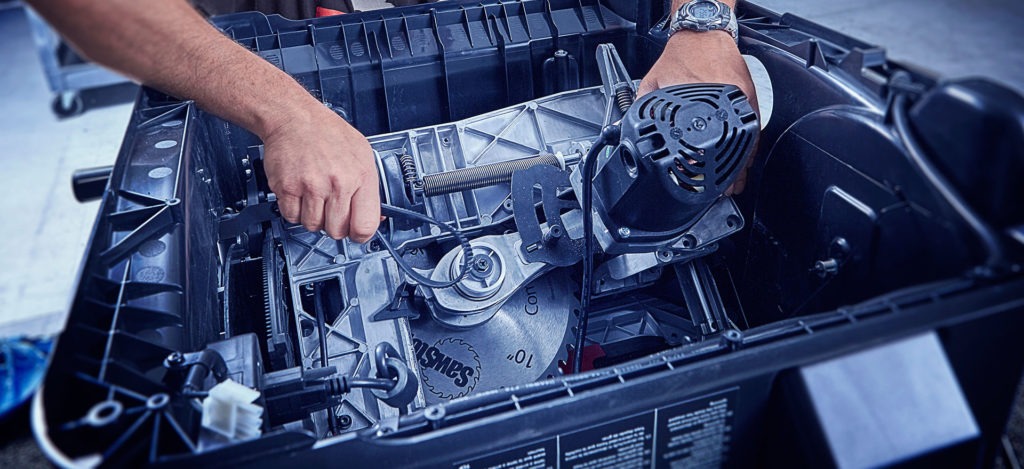

We brought cast iron, steel and a stubborn dedication to ideas like heavier. Thicker gauge. Most rigidity. Least deflection. The result of more cast-iron and steel was the heaviest weight, most powerful 10” table saw on the market. Today, almost two decades later, the Industrial Cabinet Saw still holds that honor.

The same dedication to quality materials has been brought to each saw that followed: Professional, Contractor, and Jobsite Saw Pro. SawStop accessories enjoy the same materials focus. The Sliding Crosscut Table, for example, is built from 6061 T-6 aluminum. That’s aircraft-grade. Why? Because that’s what we’d want in our tools. We figured our customers would want the same.

Owning a SawStop means having best-in-class performance without compromising your safety.

Proof is in the Performance.

SawStop’s focus on practical innovation, combined with our obsession for using the highest grade materials, produces saws unlike any before experienced by woodworkers. The ideas seem simple to most, and innovation and quality claims are easy to make. Discerning craftspeople need proof.

The proof is in each saw we build.

Find proof in our Cabinet Saws: A heavy-weight trunnion unlike any on the market, with the thickest arbors of any 10” saws. True vertical trunnion travel, with gas-piston assist for ease of operation. Durable, open gearing for minimal dust compaction and easy operation. Quiet and true poly V-ribbed belts for sure power transfer with minimal vibration. Proven 99% dust extraction, achieved through shaping the blade’s created turbulence.

Find proof in our Contractor Saw, featuring cast-iron durability coupled with the most configuration options of any SawStop saw.

Find proof in our Jobsite Saw Pro, featuring One-Turn elevation, a weight-balanced trunnion, a true t-style fence, and SawStop safety in a rugged design built for the work site.

Find proof in the tens of thousands of SawStop operators who say theirs are the best table saws ever built. And then, perhaps, find proof of your own at a dealer near you.

Check. Then Double-Check.

Our engineers and builders have every intention of creating the finest table saw, from design and materials to assembly and ultimate functionality. However, intention is not enough. We trust that the SawStop team is the best out there.

And then we verify, and verify again.

During the build process, our experts are continuously verifying that each component is built to specifications and assembled with SawStop’s stringent tolerances. Prior to shipment, batch inspections are conducted to help avoid unacceptable variations in each saw.

Finally, expert SawStop personnel in our Tualatin warehouse conduct randomized lot inspections. Confession time: at each of these steps, we sometimes find things that need fixing. We find imperfect saws, with imperfect components. But as long as our team is doing their job, you’ll never know what we found, because we never shipped it.

We engineer, build, and inspect for quality, so you can cut with confidence.